AragoCor- Industry Products

1. Water H20 Separation Filtration-Metal oxides

2. Glass, Packaging, Paints -Paper- Fillers

3. Agriculture- Feed Stock Pellets

4. Energy CCS – Nano Activity- Fracture Solutions

5. Oolitc Coolant Sports Field & Turf Cooling/ Pet Friendly Order surfactant

AragoCor- Waste Water

Aragonite is used in wastewater treatment primarily for its ability to remove pollutants and control hardness. It can be used in filters to remove heavy metals like zinc, cobalt, and lead, and it can help prevent scale buildup by forming softer, less harmful deposits. Safer than alternative Chemicals.

Key applications in wastewater treatment

• Pollutant removal:

Aragonite has been tested for its ability to remove heavy metals such as zinc, cobalt, and lead from contaminated wastewater.

It can also remove pollutants like phosphorus through a combination of electrostatic adsorption and chemical interaction.

• Hardness control:

Aragonite is often used as a non-chemical water softening method, preventing the formation of hard, clinging scale deposits that damage pipes and appliances.

Unlike calcite, aragonite forms softer, needle-like crystals that are easily flushed out, prolonging the life of equipment.

• pH buffering:

It can help maintain a stable pH level in water, which is beneficial for certain treatment processes or for protecting marine life.

• Corrosion control:

A thin film of soft aragonite can coat wetted surfaces in plumbing, protecting them from corrosive properties in the water

Methods of use

• Filters: Aragonite is used in filter cartridges, often combined with activated carbon and ion exchange resins, to remove a variety of contaminants.

• Catalyst-based systems: Some modern non-chemical water treatment systems use catalysts to promote the formation of aragonite instead of calcite to prevent scale buildup.

• Direct application: In some cases, such as in nutrient removal, aragonite can be added directly to the water as a sorbent

AragoCor- Paper,Paints & Fillers

Aragonite is used in paints and plastics as a sustainable mineral filler to improve performance and reduce costs. Its primary advantages stem from its unique needle-like crystal shape and its biogenic origin from ocean sources, which makes it an eco-friendly alternative to traditional fillers like mined lime calcium calcite.

Key applications in Plastics,Paints & Fillers

In the plastics industry, aragonite is added to a variety of resins to enhance performance and lower the overall carbon footprint of products.

• Improved mechanical properties:

Aragonite's orthorhombic crystal structure makes polymers more rigid and durable. Studies on plastics like polypropylene (PP) and polyvinyl chloride (PVC) show it can improve rigidity and, when surface-treated, can even preserve tensile strength.

• Enhanced processing:

Adding aragonite can improve the flow of plastic during extrusion and molding. It can also enhance thermal conductivity, allowing the material to heat and cool faster for greater energy savings and higher productivity.

• Cost reduction:

As an inexpensive mineral filler, aragonite is an effective and economical way to displace a portion of more costly polymer resins.

• Sustainability:

Biogenic aragonite, sourced from the ocean, is a renewable and carbon-negative mineral. For manufacturers, it offers a way to reduce the embodied carbon of products and meet sustainability goals.

• Targeted applications:

Aragonite is successfully used in:

Injection molding and extrusion: For durable, high-quality finished parts.

Bioplastics and compostable products: To strengthen the "green" profile of renewable materials.

Films and sheets: To increase durability and improve workability during extrusion

Aragonite in paints and coatings

The unique crystal shape and properties of aragonite offer several benefits when used as a filler or pigment extender in paints.

• Improved optical properties:

Because of its high refractive index, aragonite offers excellent light-scattering properties, contributing to high whiteness and improved opacity.

Color enhancement:

In addition to its high whiteness, aragonite has natural fluorescent properties. This allows it to add a pearlescent luster to paints and can increase the brilliance of mixed colors.

• Cleaner formulations:

As a naturally occurring and pure mineral, aragonite can serve as a clean, white pigment base for paints and coatings. This can replace conventional fillers that may contain impurities and require high-energy processing.

• Application-specific advantages:

Aqueous mediums: Aragonite offers good covering power in water-based paints like tempera, distemper, and casein.

Glazes and varnishes: Its crystal structure adds a pearl-like luster to oil paints when used in thin glazes.

• Sustainability:

Using biogenic aragonite as a filler and pigment extender provides a sustainable, carbon-negative alternative to conventional, mined minerals. To maximize aragonite's benefits and ensure compatibility, it is often treated with coatings.

• Surface treatment:

For use in plastics, aragonite can be surface-treated with substances like stearates. This improves bonding with the polymer matrix, which enhances dispersion and helps maintain the material's toughness.

• Preparation for paints:

For paint applications, aragonite powders may require specific preparation, but their natural charge (zeta potential) often makes them self-stabilizing against clumping in aqueous paints.

• Processing for performance:

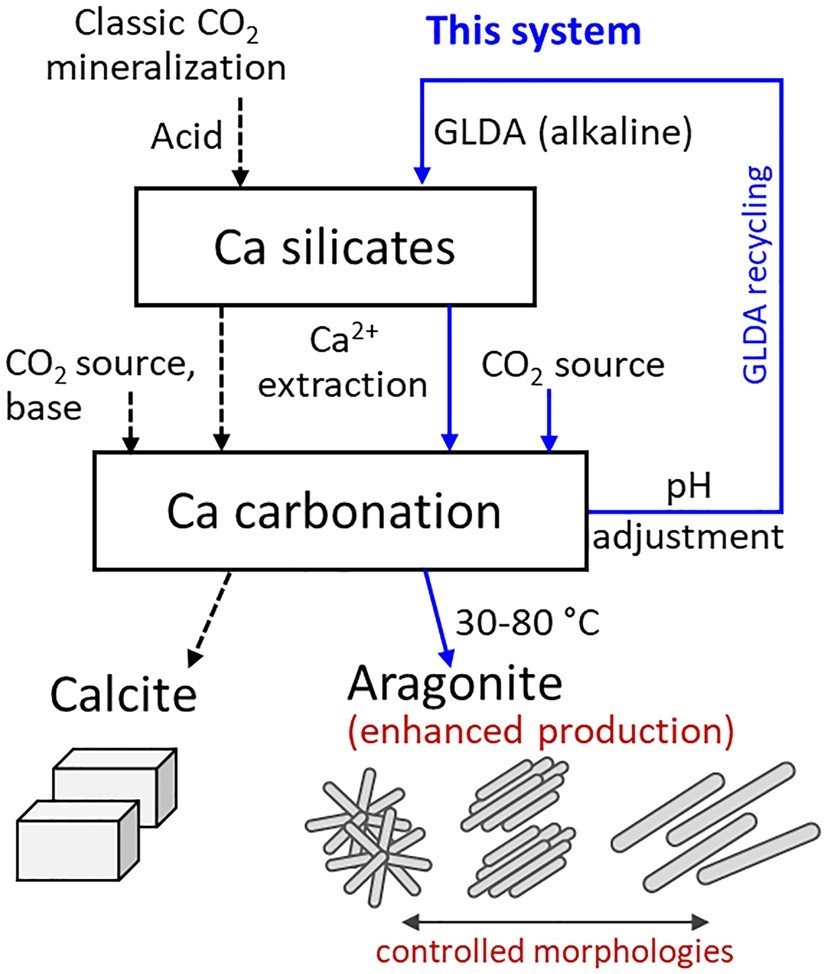

The way aragonite is synthesized can control its morphology. For example, precipitated aragonite calcium carbonate (PCC) can be eco-engineered for optimal use in paints and plastics, with different particle shapes offering varied mechanical and optical characteristics.

AragoCor- Glass Fillers

Aragonite is used in glass manufacturing as a sustainable alternative to traditional limestone. It provides manufacturers with an eco-friendly way to create high-clarity glass for various products, including container glass, architectural glass, and fiberglass.

Aragonite in new glass manufacturing ECO ENGINEERING

Aragonite is a naturally renewable form of calcium carbonate that offers several advantages over mined limestone as a raw material for glass production.

• Improves clarity:

Traditional limestone can contain iron impurities that give glass a green tint. Because oolitic aragonite has little to no iron content, it helps produce exceptionally clear glass.

• Increases efficiency:

The high purity and consistent, uniform grain size of aragonite allow for more efficient melting and processing during production.

• Reduces emissions and costs:

Aragonite is a sustainable resource with a lower carbon footprint than mined limestone. Its more efficient processing also reduces energy costs.

• Enhances equipment life:

Improved batch consistency from the use of aragonite can help extend the life of manufacturing equipment.

Aragonite for treating glass surfaces

In addition to its use in manufacturing, aragonite can also be a component of hard mineral deposits on glass surfaces, such as in aquariums.

• Formation of deposits:

In aquatic environments, aragonite can precipitate out of the water and form a white haze of calcium carbonate on glass.

AragoCor- Agriculture Feed Stock & Livestock

Aragonite is a form of calcium carbonate (CaCO₃) that is used in feedstock treatment, primarily as a source of calcium or as a catalyst precursor. In many applications, it functions similarly to other calcium-based additives like limestone and lime. Its use is noted in agricultural feed and in the production of biofuels from waste products.

Key applications in: Livestock feed

In agriculture:

• As a calcium supplement:

Feed-grade aragonite is used as a feedstock additive for livestock, including poultry and dairy cows. It provides a readily available source of calcium, which is essential for strong bones, milk and egg production, and efficient feed utilization.

• For higher bioavailability:

Anecdotal evidence suggests that aragonite's unique crystal structure may offer higher bioavailability than standard ground limestone. Some poultry producers have reported a significant reduction in egg cracking after switching to aragonite-based calcium supplements.

The process involves these steps:

• Calcination:

Aragonite (CaCO₃), or other calcium carbonate sources like limestone or waste shells, is heated to high temperatures (typically above 800°C). This thermal decomposition converts the aragonite into calcium oxide (CaO), an active catalyst for the transesterification reaction.

𝐶𝑎𝐶𝑂3Δ→𝐶𝑎𝑂+𝐶𝑂2

• Transesterification:

The CaO catalyst is introduced to a feedstock, such as waste cooking oil, and alcohol (often methanol). This process converts triglycerides in the oil into fatty acid methyl esters (FAME), which are the main component of biodiesel.

• Purification:

The CaO catalyst can be easily separated from the final biodiesel product, simplifying the purification process and reducing downstream costs.

AragoCor In biofuel production

Aragonite is a precursor to calcium oxide (CaO), a highly effective and environmentally friendly heterogeneous catalyst used in the transesterification of feedstocks like vegetable oil and animal fats to produce biodiesel.

Advantages of using aragonite

• High purity:

As a natural biogenic mineral, oolitic aragonite mineral can offer a high-purity, renewable calcium source.

• Eco-friendly:

Sourcing calcium mineral from waste materials, like seashells and concrete fines, for the synthesis of aragonite provides an environmentally friendly and cost-effective method for feedstock treatment and carbon sequestration.

• Effective catalyst:

When converted to CaO, the derived catalyst is highly effective for biodiesel production and can be reused multiple times

AragoCool- CoolSand Sports Field & Turf Cooling

Aragonite is not used in traditional temperature cooling processes like refrigeration or air conditioning.

Aragonite is Key Component for Turf

AragoCool

However, a specialized, natural form of aragonite known as oolitic aragonite is used as a cooling infill material for artificial turf.

Oolitic aragonite as an artificial turf coolant.

Artificial turf is prone to high solar heat retention, and aragonite infill helps mitigate this problem through its specific physical properties.

Heat dissipation:

The microporous structure of oolitic aragonite allows it to absorb and dissipate heat more effectively than other infill materials like crumb rubber or Silica sand which is not eco-friendly and jagged dust maker. This helps keep the turf surface cooler, making it more comfortable and safer for athletes, children, and pets. Less tare on turf and no dust application.

Safety and environmental benefits:

In addition to cooling, oolitic aragonite is a sustainable, non-toxic, and natural mineral. Its smooth, round spherical grains reduce wear on the turf, and its unique chemistry helps neutralize odors and is no silica dust applicantion.

Other temperature-related properties and uses of aragonite coolants,

While not used for general cooling, aragonite is relevant to temperature in other contexts:

• Thermodynamic instability:

Aragonite is the high-pressure, lower-temperature polymorph of calcium carbonate, stable form at standard temperature and pressure. Heating aragonite causes it to transform into calcite before it thermally decomposes.

• Paleoclimate research:

Scientists study the temperature-dependent formation of aragonite in corals and other bio minerals to reconstruct past environmental conditions.

• Magnetic water cooling treatment:

In some systems designed to prevent scale buildup, magnetic fields are used to influence the crystallization of calcium carbonate. This encourages the formation of aragonite crystals instead of calcite. The aragonite forms a loose sludge rather than a hard, insulating scale, which improves the heat transfer efficiency of the equipment.

AragoCooL for Pets & Playgraounds

• Pets and Play Grounds:

We all want to keep our love ones Cool not over heat them when the play.

• Arago-Cool will do just that Oolitic Aragonite Eco-Engineered to keep the tempature of your play field or play ground cool all summer long.

• Nature made to stay cool like the Ocean.

• Oolitic Aragonite also is ideal for you house or dog play area.

• Arago-Cool also has a neutralizing composition to absorb the ammonia form the urine to reduce your pet playground smells letting you enjoy even in the summer heat.

GO Green 2030 Make Net Zero Goals !

ARAGOCOR MINERALS

DOING OUR PART FOR TOMORROWS ECO ENGINEED

2030 - NET ZERO CO2

The majority of today’s offsets fall into a category called “avoided emissions”. These projects either rely on alternatives to using fossil fuels, avert emissions from waste, or protect forests. All of which (if performed correctly) reduce the volume of GHGs being added to the atmosphere. The second category of offsets is “REMOVAL OF CO2”, which, as their title implies, remove carbon dioxide from the atmosphere by storing it away.

These projects can include technology like Direct Air Capture (DAC), or

Absorption Capture “AragoCor Minerals”

planting back to mother earth OR the use of Oceans Eco-Engineered Nature Core “CCS’’ Carbon Capture Storage Process with AragoCor Minerals.

ARAGOCOR IS THE ECO FRIENDLY OCEAN RENEWABLE MINERALS TO CAPTURE CARBONS TO BE STORED SAFELY.

MANY INDUSTRIES USES for ARAGOCOR MINERALS

IN TODAYS MONDERN FAST PACE WORLD.

ARAGOCOR MIMERALS SHOULD BE YOUR GO TO ECO-RENEWABLE AND SUSTANIABLE SOLUTIONS.

KEEP YOUR COMPANY OR INDUSTRY ON TRACK FOR “CCS” CARBON CAPTURE STORAGE FOR GO GREEN 2030 PROCESS

STAY ON TRACK HELP MOTHER EARTH.

CO2 REMOVAL OFFSET EVERY TON HELPS TODAY.